With a 30-year history in the industry, Lechang Yuhuang Electronic Technology Co., Ltd has solidified its status as a dependable screw factory—and this long-standing trust is rooted in every detail of its production workflow. Each stage of manufacturing has been polished through decades of the team’s practical expertise, ensuring that every Screw, nut, and bolt meets the same high standards of durability and reliability as the clients who have relied on them for years. Below is a detailed walkthrough of the production process, just as we present it to clients during workshop visits:

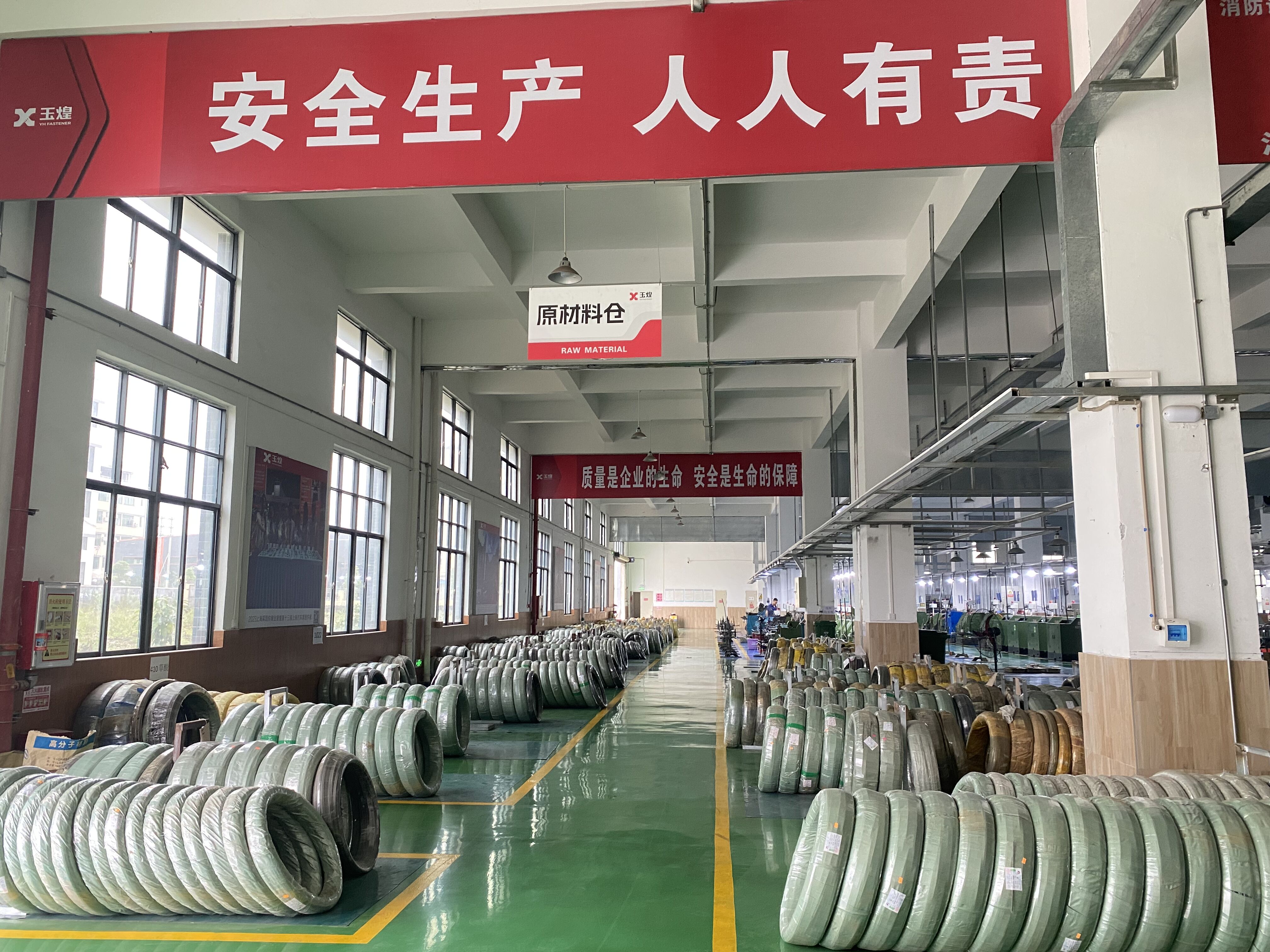

Lao Li, the company’s purchasing manager, has maintained stable partnerships with key steel suppliers for over a decade, while also collaborating with several specialized vendors to diversify sourcing channels. This multi-supplier strategy offers two critical advantages. Firstly, it ensures a steady supply of raw materials even amid market fluctuations, avoiding production disruptions that could impact client timelines. Secondly, it allows for swift responses to quality issues. For example, when Lao Li discovered scratches on a batch of stainless steel, he promptly rejected the shipment and secured alternative materials from a backup supplier—all while keeping production on track.

The IQC station is overseen by Xiao Li, whose keen eye for defects has been honed through years of experience. She utilizes a high-precision spectrometer to analyze the material composition of incoming raw materials, leaving no room for substandard inputs. If a sample’s tensile strength falls even 3% below the required industry standard, The entire batch of products was immediately marked as rejected - an uncompromising move that aligns with the company's focus on quality over the past three decades.

Heading machines are the backbone of the workshop, and as a 30-year-old enterprise, Lechang Yuhuang prioritizes equipment upgrades to stay at the forefront of manufacturing. The company replaces these machines with the latest generation of models each year, and Master Zhang, a veteran operator with years of tenure, calibrates them every morning before production begins. He has a deep understanding of adjusting pressure for different screw types—particularly for Machine Screw, where precise head height is essential to fit seamlessly into machine slots. Master Zhang conducts sample checks every 15 minutes without fail; on one occasion, he noticed slightly uneven screw heads being produced and immediately shut down the machine, stating, “Losing an hour of production is better than risking our 30-year reputation with defective parts.”

When manufacturing Set Screw, the company alternates between roll threading and cut threading based on the material— a technique refined over its 30-year history. Xiao Ming, a young technician who learned the skill from Master Zhang, explains: soft brass materials use cut threading to ensure cleaner thread lines, while hard steel materials require roll threading to boost thread strength. Xiao Ming also keeps a small notebook to record optimal machine settings for each customer’s order, a practice passed down through the company’s decades of operations. Last week, he noted that a German client’s Set Screw required finer threads and adjusted the machine parameters accordingly, ensuring the final product met the client’s exact specifications.

Random inspections are conducted every few minutes during the screw production process— a rigorous step that has been part of the company’s quality control system for years. If any defects or issues are detected in the screws, production is halted immediately. All screws manufactured before the problem was identified are discarded to ensure only qualified products move on to subsequent stages. This strict inspection process effectively stops the spread of defective products and maintains the consistent quality that has defined Lechang Yuhuang over its 30-year journey.

Lao Chen, who has operated the heat treatment oven for 12 years, manually controls the heat treatment duration— a task he performs with the precision expected of a team member at a 30-year enterprise. Carbon steel materials are heated at 850°C for 2 hours and then quenched in oil, while stainless steel materials undergo annealing at 1050°C for 1 hour. Once, he stayed late to reprocess a batch of materials after the oven temperature dropped by 10°C, saying, “Heat treatment is the key to ensuring the strength of screws, nuts, and bolts— we’ve built our reputation on this, so there are no shortcuts.”

The plating room provides three main plating options, with selections tailored to customer needs— a service refined to meet diverse client demands over 30 years. For example, Mr. Liu from a automobile company consistently chooses zinc plating for his screws due to its cost-effectiveness and rust resistance. In contrast, a marine client opts for chrome plating for their nut and bolt packages to withstand saltwater corrosion. Xiao Hong, the plater, ensures an even plating layer; on one occasion, she stripped the plating from an entire batch and re-plated them simply because she found a tiny unplated spot— a level of care that has kept clients returning for years.

Before product sorting, a series of comprehensive real-world tests are conducted to verify quality— a final check that upholds the company’s 30-year standard of excellence. First, the company’s optical inspection machine performs initial screening, automatically detecting surface defects such as scratches, burrs, or uneven plating on Screws, nuts, and bolts— removing visually unqualified products early on. Next, mechanical performance tests are carried out: screws are clamped in a tensile tester to measure load-bearing capacity. Once, a client’s industrial screws required a 500kg load-bearing capacity, and the company tested them up to 600kg to ensure safety. Nut and bolt packages also undergo torque tests to prevent thread stripping during tightening. For outdoor-use parts, a 48-hour salt spray test is conducted— any sign of rust results in immediate rejection.

Flexible packaging plays a key role in logistics, cost management, and customer usability— and over 30 years, Lechang Yuhuang has perfected this to meet client needs. Automatic packaging machines are used to enhance efficiency, but the company also offers fully customized packaging based on customer requests. For example, a large automotive parts manufacturer typically orders fasteners in bulk cartons, ideal for their high-volume assembly lines. Meanwhile, a precision equipment company may request custom-sealed packaging— such as packs with anti-rust film and product traceability labels— to protect components during transit, a solution developed based on decades of understanding client logistics challenges.

Before shipment, Lao Hu, the warehouse manager, performs random spot checks— a final step that reflects the company’s 30-year commitment to accuracy. He opens one out of every 20 boxes to verify quantity— even if a single screw is missing, the entire order is repackaged. He also confirms that package labels align with order requirements, ensuring clients receive exactly what they ordered, every time.

This is more than just a “production process”— it is the daily work ethic of a team that has built a 30-year legacy of trust. The company does not merely manufacture Screws, nuts, and bolts; it ensures these products solve customers’ problems, a promise that has guided its operations for three decades. That is what sets a reliable, long-standing screw factory apart from the rest— and makes Lechang Yuhuang a partner you can trust for years to come.

Lechang Yuhuang Electronic Technology Co., Ltd

Email: [email protected]

WhatsApp/WeChat/Phone: +8613528527985

Copyright © Yuhuang Technology Lechang Co., LTD | Privacy policy