How Stainless Steel Sealing Screws with O-Rings Prevent Leaks

What Are Sealing Fasteners and How Do They Work?

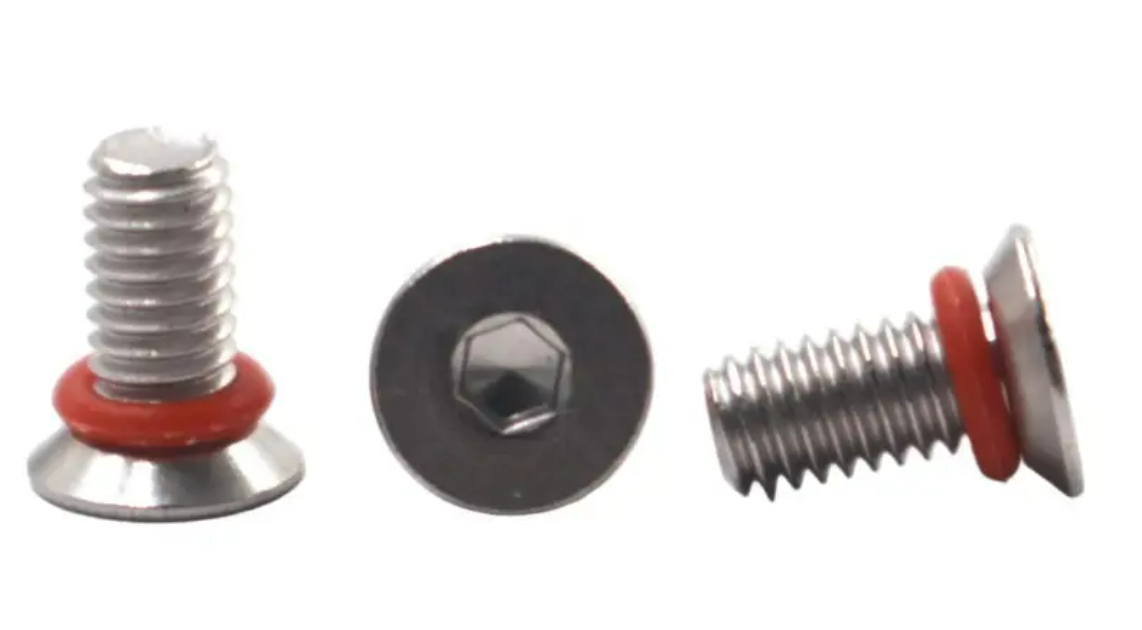

Sealing fasteners represent a special type of screw with built-in O-rings that stop leaks effectively. What makes them different from regular screws? Well, there's actually a small groove right under the head where the O-ring sits. When these screws get tightened down, this groove squeezes the O-ring creating what amounts to a full circle seal around the entire connection point. The result? No water getting in, no dust making its way through, and definitely no harmful chemicals entering from outside. Plus, it keeps whatever fluid might be inside from escaping either. Industry studies looking at sealing tech show something interesting too. The amount of pressure applied during installation has been carefully figured out so the O-ring stays flexible even when temperatures change over time. This means the seal lasts longer without breaking down or losing strength, which is exactly what manufacturers need for their products to work properly year after year.

The Difference Between Standard Screws and Integrated Sealing Screws

Regular screws need extra gaskets or glue to stop leaks, but these methods often fail when there's vibration or temperature changes happening. Integrated sealing screws do things differently by combining both fastening and sealing functions in one part. During installation, the O ring sits firmly in place within its groove, which works well even under pressure conditions. When the metal screw head touches the surface it's going into, this creates stability for the whole seal setup. The metal contact actually takes some strain off the rubber part, making everything last longer than what we see with conventional gasket arrangements most of the time.

Design of Sealing Screws with Groove-Integrated O-Rings for 360° Compression

Sealing screws work best when they have grooves that are machined with real precision. These grooves manage how much the O-ring gets compressed, usually around 20 to 30 percent of what it was originally thick. This sweet spot makes sure the seal works well and lasts longer too. If we compress the ring too much, it might crack over time. Not enough compression leaves spaces where leaks can happen. The grooves themselves need to be made by CNC machines with tolerances below 0.1 mm. This level of accuracy creates even pressure all around the ring, so the seal stays good even if the surface isn't perfectly flat. Another nice feature is that captive O-rings stay put during installation, which means they can be used again after maintenance. This really matters for industries that require frequent checks and repairs, such as aircraft manufacturing or shipbuilding operations where downtime costs money.

Material Advantages: Why Stainless Steel Is Ideal for Sealing Screw Applications

Superior Corrosion Resistance in Harsh and Humid Environments

The chromium found in stainless steel creates what we call a passive oxide layer that basically repairs itself when exposed to air and water, which is why it doesn't rust easily even when submerged in seawater for extended periods. Research conducted over several decades indicates that this protective film can offer anywhere from three to five times better protection against humidity compared to regular carbon steel varieties. What really sets stainless steel apart though is how resistant it is to something called galvanic corrosion. That makes it particularly well suited for chemical processing facilities. In fact, tests have shown that after being continuously exposed to moisture for as long as 5,000 hours straight, stainless steel still manages to hold onto around 98% of its original tensile strength. No wonder so many industries rely on it for their most demanding applications.

Comparison of Stainless Steel vs. Carbon Steel and Other Metals

Unlike carbon steel, which becomes brittle through oxidation cycles, stainless steel maintains structural integrity over time. Polymer-coated carbon fasteners typically degrade within two years in marine settings, whereas stainless steel variants show no measurable deterioration over the same period. This resilience prevents microgaps that could compromise sealed joints.

Industry Data on Longevity in Marine and Outdoor Applications

In coastal environments, stainless steel sealing screws offer 15+ years of service life—significantly longer than the 3–5 years typical for coated alternatives. Their UV resistance prevents surface degradation, contributing to sustained seal performance. A 2024 survey of offshore operators found that 92% reported no fastener replacements needed after ten years of use.

O-Ring Integration and Material Selection for Maximum Seal Performance

Achieving a Hermetic 360-Degree Seal Through Precision O-Ring Grooves

The ring shaped groove that surrounds the screw shank actually puts pressure on the O ring from all sides, forming a full circle seal that keeps out both liquids and gases better than regular flat gaskets ever could. When manufacturers use CNC machines to cut these grooves, they can keep the measurements really tight, about 0.1 mm difference at most. This allows for just the right amount of squeeze on the O ring between 15% and 30%, which works well even when temperatures swing from super cold at minus 40 degrees Fahrenheit all the way up to scorching hot 450 F. Maintaining this kind of sealing power matters a lot in places where conditions change constantly throughout operation.

Buna-N, Viton, Silicone, and Fluorosilicone: Matching O-Ring Material to Environment

| Material | Temperature Range | Chemical Resistance | Cost |

|---|---|---|---|

| Buna-N | -30°F to 250°F | Oils, fuels | $ |

| Viton® | -15°F to 400°F | Acids, hydrocarbons | $$ |

| Silicone | -80°F to 450°F | Water, ozone | $$ |

| Fluorosilicone | -65°F to 350°F | Solvents, aerospace fluids | $$$ |

For jet fuel systems, fluorosilicone reduces failure rates by 63% compared to standard silicone. In solar panel mounts exposed to wide temperature swings, silicone offers superior flexibility and UV stability.

Temperature, Chemical, and UV Resistance by O-Ring Compound

The desalination industry relies heavily on Viton® O-rings because these seals can handle both chlorine and prolonged saltwater contact without losing their shape or flexibility even at temperatures reaching around 400 degrees Fahrenheit. When it comes to farming equipment, Buna-N remains a popular choice among manufacturers since it stands up well against various types of biofuel that might otherwise degrade standard rubber components over time. Outdoor applications where ozone becomes a concern often turn to EPDM materials instead. These compounds actually tolerate ozone concentrations as high as 50 parts per million, which happens to be about double what silicone can manage before breaking down. That makes EPDM particularly suitable for environments where constant exposure to harsh weather conditions is expected.

Critical Applications of Sealing Screws in Demanding Industries

Marine Equipment: Preventing Saltwater Ingress and Corrosion

Stainless steel sealing screws with 316-grade material and chemically resistant O-rings prevent chloride-induced corrosion at critical joints. Vessels using these fasteners saw a 34% reduction in equipment replacement costs in salt spray testing, highlighting their value in extending system lifespan.

Aerospace Systems: Maintaining Integrity Under Vibration and Pressure

In aerospace, sealing screws maintain cabin pressure and fuel system integrity under extreme vibration. The precision groove design ensures consistent O-ring compression even under 15G shock loads. Jet engine manufacturers report zero leakage incidents in turbine housing assemblies after 50,000 flight-hour simulations.

Medical Devices: Ensuring Sterility and Leak-Free Enclosures

Medical device makers use sealing screws to create bacteria-resistant enclosures for sterilization chambers and fluid delivery systems. The 360° seal withstands over 200 autoclave cycles without degradation. With FDA guidance emphasizing hermetic sealing for Class III implantable devices, demand for medical-grade fasteners is growing at 28% annually.

Best Practices for Installing Stainless Steel Sealing Screws Without Compromising the O-Ring

Proper installation is essential to achieving leak-free performance and long-term reliability. Research indicates that 23% of sealing failures stem from installation errors rather than design flaws (Mechanical Sealing Journal, 2023). Following best practices minimizes risk and ensures optimal function across critical applications.

Common Installation Mistakes That Break the Seal

Over-tightening is the leading cause of failure, permanently deforming the O-ring beyond its elastic limit. Poor surface preparation—such as leaving burrs or debris—can tear the elastomer during assembly. Even minor cross-threading creates micro-leak paths that undermine the full 360° seal.

Recommended Torque Settings and Assembly Tools

| Application | Torque Range (Nm) | Tool Type |

|---|---|---|

| Marine equipment | 5.8–7.2 | Preset torque wrench |

| Medical devices | 2.5–4.0 | Anti-backlash screwdriver |

| Aerospace panels | 9.0–11.5 | Electropneumatic driver |

Using calibrated tools prevents over-compression. Nylon-tipped drivers protect the O-ring from nicks, while fluorosilicone-coated tips reduce friction heat when installing M6 screws in corrosive settings.

Training Technicians for Reliable, Zero-Failure Sealing Processes

Certification programs with hands-on training reduce installation defects by 41% (Assembly Engineering Council, 2024). Effective modules simulate real-world challenges—like confined-space installations—and emphasize:

- Visual inspection of groove alignment

- Use of FDA-approved silicone lubricants

- Post-installation leak testing via pressure decay or bubble immersion

Regular competency audits help maintain the balance between secure fastening and O-ring protection, ensuring consistently reliable seals.

FAQ

What are sealing fasteners?

Sealing fasteners are special screws with built-in O-rings designed to prevent leaks by forming a complete seal.

Why is stainless steel preferred for sealing screws?

Stainless steel offers superior corrosion resistance, especially in harsh environments, making it ideal for sealing applications.

How does the groove-integrated O-ring work?

The groove-integrated O-ring is machined to create a 360° seal by compressing the O-ring precisely around the screw.

What industries commonly use sealing screws?

Industries like marine, aerospace, and medical heavily rely on sealing screws for their zero-leak and corrosion-resistant properties.

Table of Contents

- How Stainless Steel Sealing Screws with O-Rings Prevent Leaks

- Material Advantages: Why Stainless Steel Is Ideal for Sealing Screw Applications

- O-Ring Integration and Material Selection for Maximum Seal Performance

- Critical Applications of Sealing Screws in Demanding Industries

- Best Practices for Installing Stainless Steel Sealing Screws Without Compromising the O-Ring