Our range of security screws, including Button Head Tamper - Proof Torx Security Screw, Pan Head Triangular Slot Security Screw, Pan Head Y - Slot Security Screw, and Countersunk Head Y - Slot Security Screw, is designed to provide maximum tamper resistance and durability. We alsosupply security bolts and screws, torx security machine screw, and specialty security screw solutions to meet the diverse fastening needs of industries requiring enhanced safety. Manufactured from premium materials such as stainless steel and alloy steel, these fasteners are engineered for high strength, corrosion resistance, and secure installation, ensuring reliable performance even in demanding environments.

|

Attribute |

Details |

|

Product Name |

Security Screws – including Pan Head Triangular Slot, Button Head Tamper-Proof Torx, Pan Head Y-Slot, Countersunk Head Y-Slot, and specialty tamper-resistant fasteners |

|

Material Options |

Premium stainless steel, alloy steel, and custom materials available upon request for specific environmental or strength requirements |

|

Drive Types |

Triangular slot, Y-slot, Torx security, and other tamper-resistant profiles to prevent unauthorized removal |

|

Head Styles |

Pan head, button head, countersunk head, and custom head designs to suit diverse installation needs |

|

Surface Finish |

Zinc plating, black oxide, nickel plating, passivation, anodizing, or customized coatings for enhanced corrosion resistance and visual appeal |

|

Thread Types |

Metric and UNC/UNF thread standards, with precision manufacturing for reliable fit and torque performance |

|

Sizes Available |

Full range of standard sizes; custom dimensions produced to client specifications for OEM/ODM orders |

|

Applications |

Designed for industries requiring high-security fastening such as electronics, outdoor equipment, public facilities, and industrial machinery |

|

Customization Service |

Complete OEM/ODM support including head style modification, drive type customization, material selection, and bulk production capabilities |

|

Quality Standards |

Manufactured under strict quality control processes to meet ISO, DIN, ANSI, and other international standards |

Tamper-Proof Design – Specialized drive styles, such as Torx, Y-slot, and Triangular slot, significantly reduce the risk of unauthorized removal.

High Material Quality – Produced with stainless steel, alloy steel, and other premium materials for outstanding strength and corrosion resistance.

Versatile Head Styles – Options including button head, pan head, and countersunk head to suit varied installation requirements.

Wide Industry Coverage – Suitable for sectors from electronics to heavy industry, aligning with our company’s capability to produce high-performance custom fasteners.

Custom Manufacturing – Dimensions, coatings, and head types can be tailored to meet specific operational needs without compromising on quality or compliance.

Q: Are you a trading company or manufacturer?

A: We are a manufacturer with over 30 years of expertise in precision and non-standard fasteners, equipped with automated production lines and advanced inspection facilities.

Q: Can you produce non-standard set screws?

A: Yes, we specialize in custom threads, left-hand configurations, unique drive types, and special coatings according to your drawings or samples.

Q: What materials can you supply?

A: We work with carbon steel, stainless steel,brass, and other special alloys.

Q: Do you provide samples?

A: Yes. Stock items are free (freight at buyer’s cost). Custom items may require tooling charges, with small samples shipped at our cost.

Q: What is your delivery time?

A: Standard products can be shipped within days; custom orders are typically completed within 15–20 working days, depending on complexity.

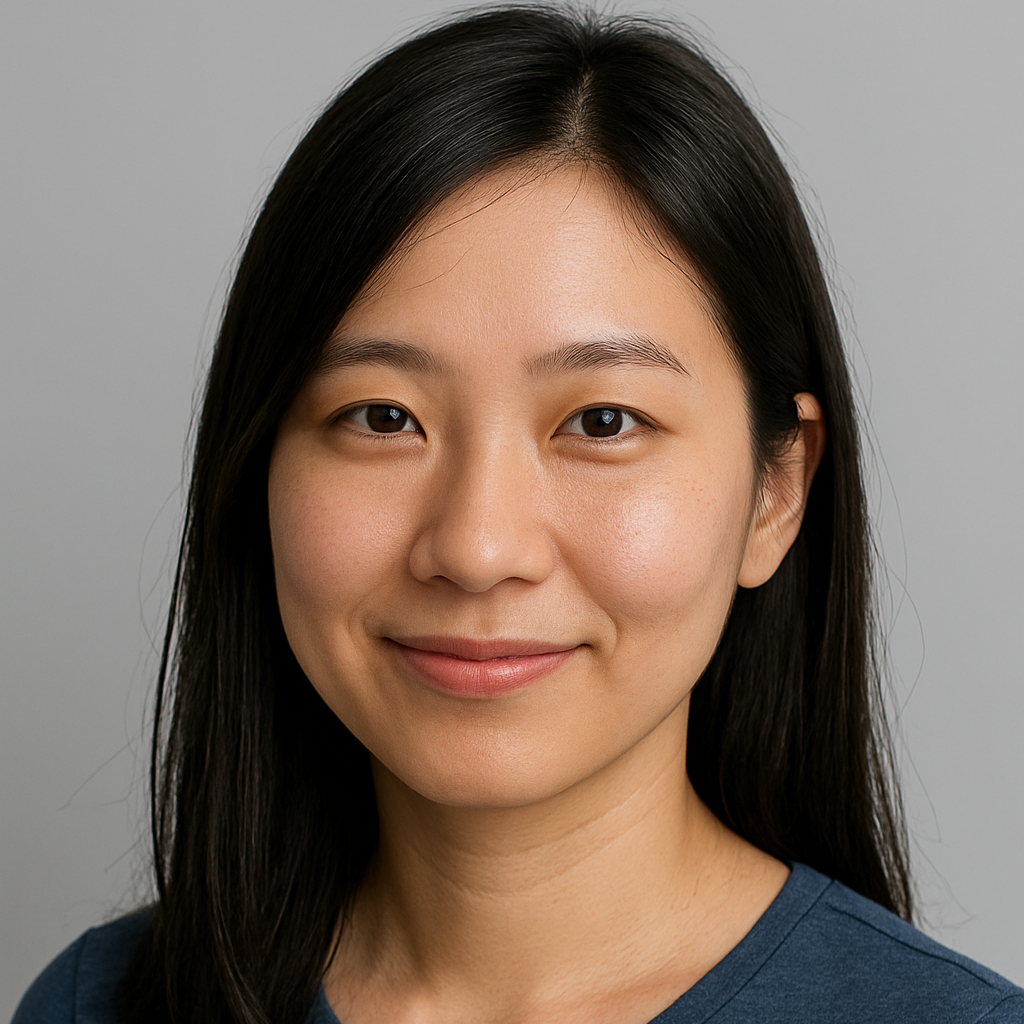

Excellent products, excellent service. Super friendly staff. Joan Chen provides an amazing customerservice. Always on top of things, ready to help. Super happy with what i get.

The product quality is excellent and not only the employees are fast in response in every quotation the mechanical engineers that work in the company have made reality every customisation

Excellent, the delivery was very fast, the product quality is as we expected, they fit our design and allthe time the supplier had contact with us.

Copyright © Yuhuang Technology Lechang Co., LTD | Privacy policy