High-quality anti-loosening screws with blue Nylok thread for secure fastening. Available in M2, M3, M4, M5, M6, M8, and M10 sizes with Torx flat or countersunk heads. Ideal for electronics, machinery, and industrial assemblies. OEM customization and bulk orders supported for reliable, vibration-resistant applications.

Material |

Brass/Steel/Alloy/Bronze/Iron/ Carbon steel/etc |

Grade |

4.8/ 6.8 /8.8 /10.9 /12.9 |

specification

|

M0.8-M16 or 0#-1/2" and we also produce according to customer's requirement |

Standard |

GB,ISO,DIN,JIS,ANSI/ASME,BS/custom |

Lead time |

10-15 working days as usual,It will based on the detailed order quantity |

Certificate |

ISO14001/ISO9001/IATF16949 |

Color |

We can provide customized services according to your needs |

Surface Treatment |

We can provide customized services according to your needs |

# |

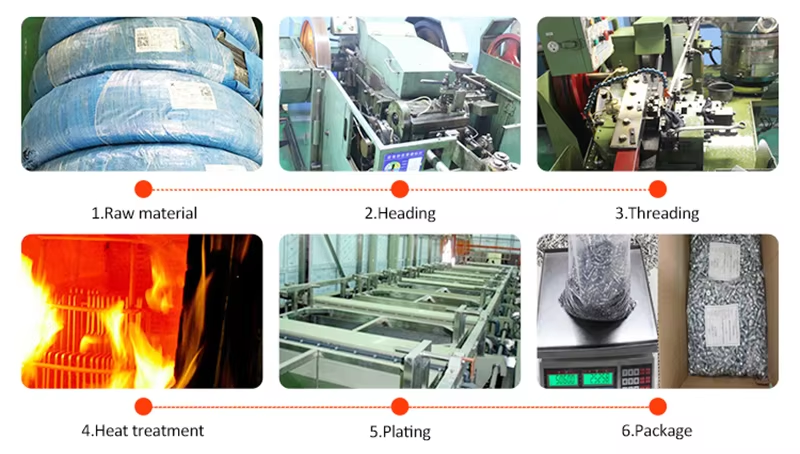

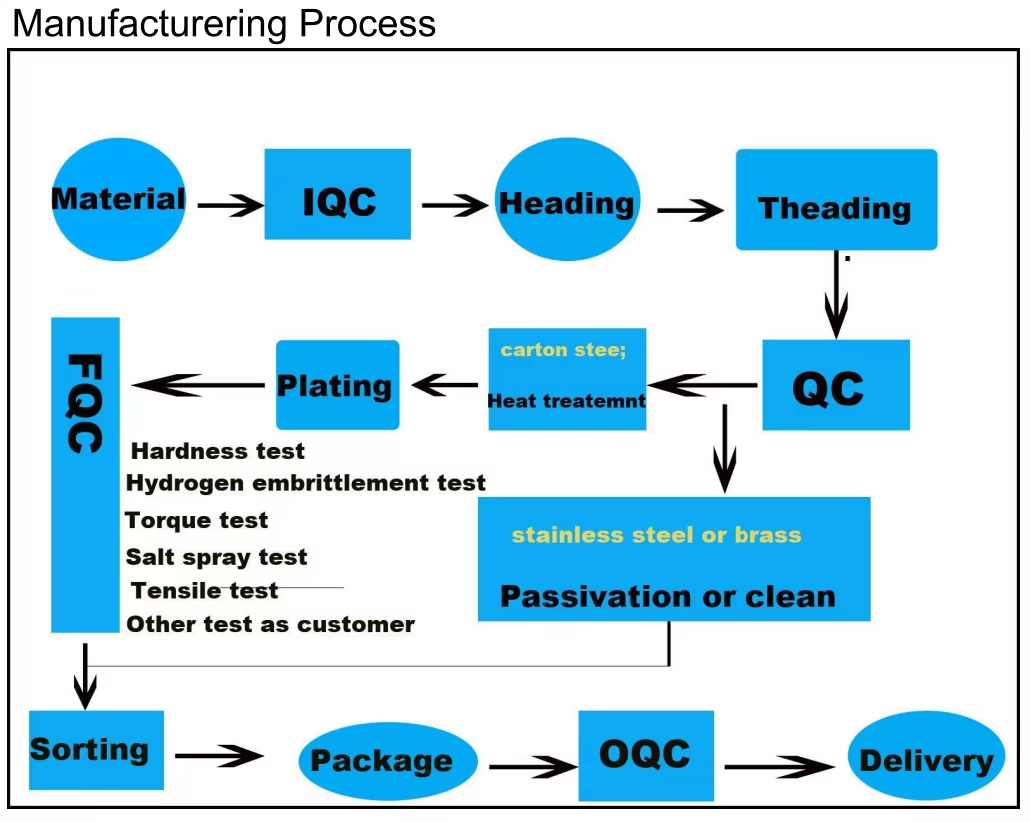

Process Name |

Checking Items |

Detection frequency |

Inspection Tools/Equipments |

1 |

IQC |

Check raw material: Dimension, Ingredient, RoHS |

Caliper, Micrometer, XRF spectrometer |

|

2 |

Heading |

Outward appearance, Dimension |

First parts inspection: 5pcs each time Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual |

3 |

Threading |

Outward appearance, Dimension, Thread |

First parts inspection: 5pcs each time Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual, Ring gauge |

4 |

Heat treatment |

Hardness, Torque |

10pcs each time |

Hardness Tester |

5 |

Plating |

Outward appearance, Dimension, Function |

MIL-STD-105E Normal and strict single sampling plan |

Caliper, Micrometer, Projector, Ring gauge |

6 |

Full Inspection |

Outward appearance, Dimension, Function |

Roller machine, CCD, Manual |

|

7 |

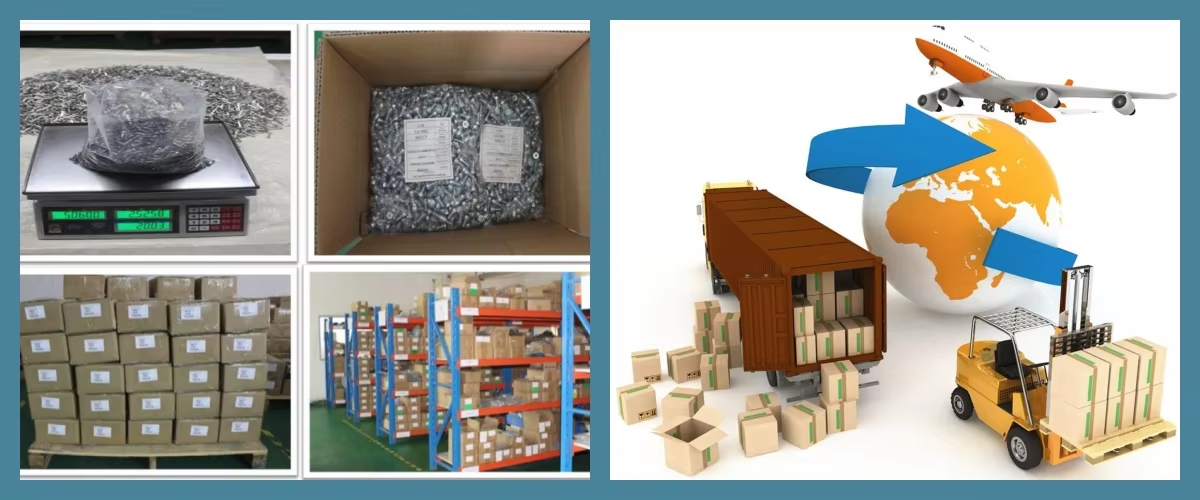

Packing&Shipment |

Packing, Labels, Quantity, Reports |

MIL-STD-105E Normal and strict single sampling plan |

Caliper, Micrometer, Projector, Visual, Ring gauge |

Exhibition

|

#

|

Process Name

|

Checking Items

|

Detection frequency

|

Inspection Tools/Equipments

|

|

1

|

IQC

|

Check raw material: Dimension, Ingredient, RoHS

|

Caliper, Micrometer, XRF spectrometer

|

|

|

2

|

Heading |

Outward appearance, Dimension

|

First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual

|

|

3

|

Threading |

Outward appearance, Dimension, Thread

|

First parts inspection: 5pcs each time

Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual, Ring gauge

|

|

4

|

Heat treatment

|

Hardness, Torque

|

10pcs each time

|

Hardness Tester

|

|

5

|

Plating

|

Outward appearance, Dimension, Function

|

MIL-STD-105E Normal and strict single sampling plan

|

Caliper, Micrometer, Projector, Ring gauge

|

|

6

|

Full Inspection

|

Outward appearance, Dimension, Function

|

Roller machine, CCD, Manual

|

|

|

7

|

Packing&Shipment

|

Packing, Labels, Quantity, Reports

|

MIL-STD-105E Normal and strict single sampling plan

|

Caliper, Micrometer, Projector, Visual, Ring gauge

|

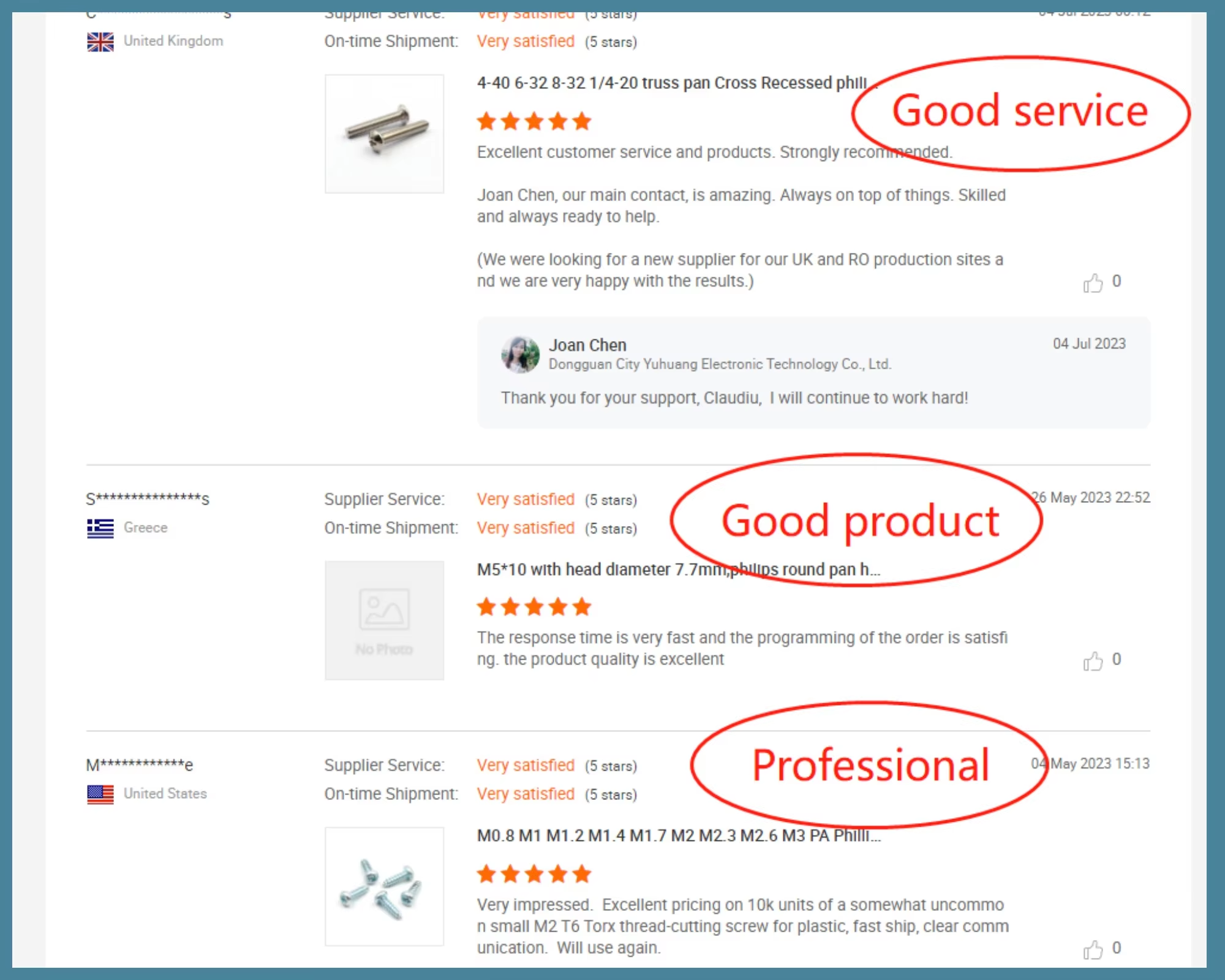

Excellent products, excellent service. Super friendly staff. Joan Chen provides an amazing customerservice. Always on top of things, ready to help. Super happy with what i get.

The product quality is excellent and not only the employees are fast in response in every quotation the mechanical engineers that work in the company have made reality every customisation

Excellent, the delivery was very fast, the product quality is as we expected, they fit our design and allthe time the supplier had contact with us.

Copyright © Yuhuang Technology Lechang Co., LTD | Privacy policy