High-quality stainless steel 304 rivet nuts with small flange and half-hex design. Ideal for secure fastening in sheet metal, panels, and assemblies. Flat head ensures flush installation. Custom sizes and bulk factory orders supported for industrial, automotive, and electronics applications.

# |

Process Name |

Checking Items |

Detection frequency |

Inspection Tools/Equipments |

1 |

IQC |

Check raw material: Dimension, Ingredient, RoHS |

Caliper, Micrometer, XRF spectrometer |

|

2 |

Heading |

Outward appearance, Dimension |

First parts inspection: 5pcs each time Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual |

3 |

Threading |

Outward appearance, Dimension, Thread |

First parts inspection: 5pcs each time Regular inspection: Dimension -- 10pcs/2hours; Outward appearance -- 100pcs/2hours |

Caliper, Micrometer, Projector, Visual, Ring gauge |

4 |

Heat treatment |

Hardness, Torque |

10pcs each time |

Hardness Tester |

5 |

Plating |

Outward appearance, Dimension, Function |

MIL-STD-105E Normal and strict single sampling plan |

Caliper, Micrometer, Projector, Ring gauge |

6 |

Full Inspection |

Outward appearance, Dimension, Function |

Roller machine, CCD, Manual |

|

7 |

Packing&Shipment |

Packing, Labels, Quantity, Reports |

MIL-STD-105E Normal and strict single sampling plan |

Caliper, Micrometer, Projector, Visual, Ring gauge |

|

Material

|

Brass/Steel/Alloy/Bronze/Iron/ Carbon steel/etc

|

|

Grade

|

4.8/ 6.8 /8.8 /10.9 /12.9

|

|

specification

|

M0.8-M16 or 0#-1/2" and we also produce according to customer's requirement

|

|

Standard

|

GB,ISO,DIN,JIS,ANSI/ASME,BS/custom

|

|

Lead time

|

10-15 working days as usual,It will based on the detailed order quantity

|

|

Certificate

|

ISO14001/ISO9001/IATF16949

|

|

Color

|

We can provide customized services according to your needs

|

|

Surface Treatment

|

We can provide customized services according to your needs

|

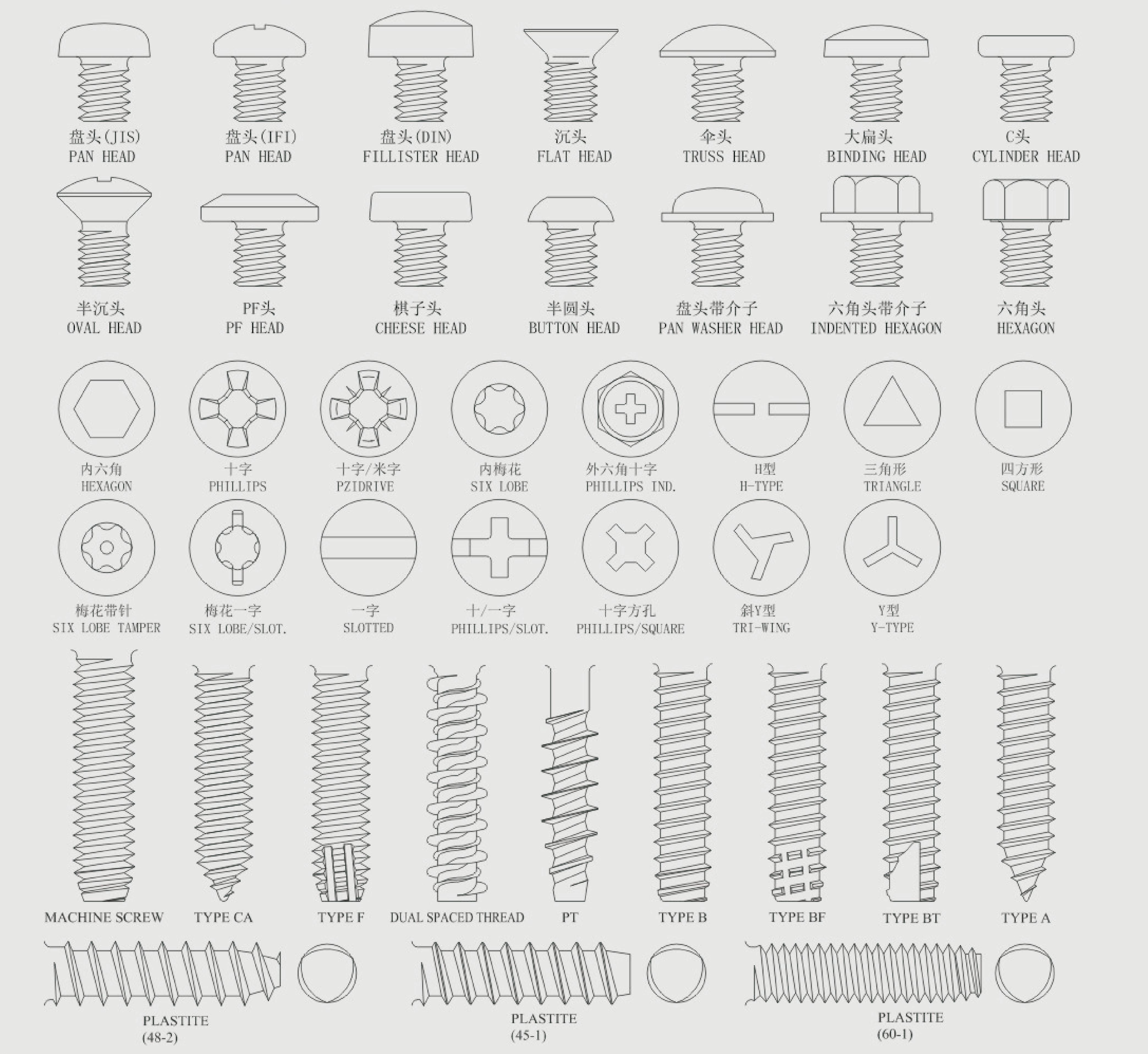

Screw type

|

Q1:Are you a factory or a trading company?

We are manufacturer .

1.thus making sure you get the products with best price.

2.working with us, Factory direct sales, quality is more guaranteed.

3.however, in order to meet the needs of customers, we can also help customers integrate resources and assist customers in purchasing. (We are a manufacturer for making kinds of fasteners over 25 years, we have superior relevant suppliers.)

Q2:What types of customized parts do you provide?

It can be made according to the drawings and specifications provided by customers.for your special needs. we manufacture suitable fasteners according to your product characteristics.

Q3:Do you provide samples ? is it free or extra ?

Yes, if we had stock the available goods or have available toolings, we could offer the sample for free charge within 3 days ,but do not pay the cost of freight.

If the products is custom maked for my company, I will charge the tooling charges and supply the samples for customer approval within 15 working days.

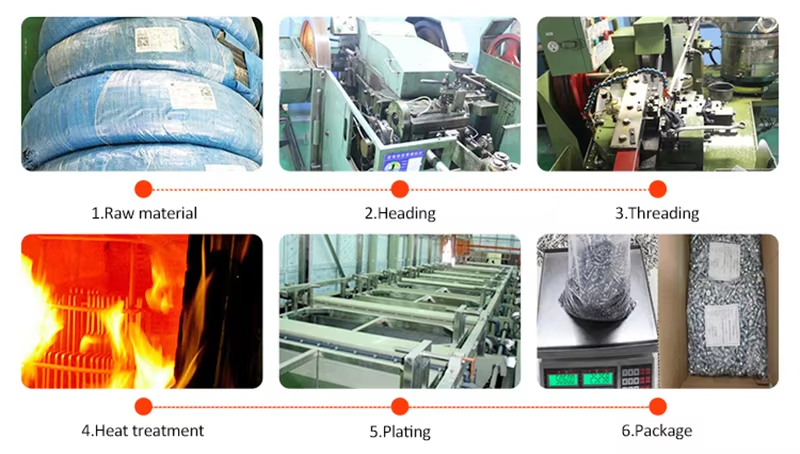

Q4:How does your company guarantee product quality?

1.Each link of our products has a corresponding department to monitor the quality.From the source to the delivery, the products are in strict accordance with THE ISO process, from the previous process to the next process flow, all are confirmed that the quality is correct before the next step.

2.We have a special quality department responsible for the quality of the products. The screening method will also be based on different screw products, manual screening, machine screening.

3.We have fully inspection systems and equipments from material to products, each step confirm the best quality for you.

Excellent products, excellent service. Super friendly staff. Joan Chen provides an amazing customerservice. Always on top of things, ready to help. Super happy with what i get.

The product quality is excellent and not only the employees are fast in response in every quotation the mechanical engineers that work in the company have made reality every customisation

Excellent, the delivery was very fast, the product quality is as we expected, they fit our design and allthe time the supplier had contact with us.

Copyright © Yuhuang Technology Lechang Co., LTD | Privacy policy